Visiting the home of Syntace

We headed down to Tacherting in southern Baveria to see how Syntace lives up to its maxim "Form Follows Function."

When you visit the Syntace website, the founder Jo Klieber’s maxim “Form Follows Function” cannot be missed. With this and the following quote in mind, here is a recount of our visit to the Syntace Headquarters in Tacherting, just north of Lake Chiemsee in beautiful southern Baveria with a scenic Alpine backdrop…

The guiding principle, Jo Klieber:

"The laws of physics are not concerned with us, but we must pay attention to them - especially when there's a headwind! By applying technology and science to the bicycle, we are able to build human-powered machines that carry us over mountains and down the road with more speed and efficiency than ever before, thereby unleashing your full potential.

In order to achieve this, theoretical knowledge and practical experience have to be turned into reasonably-priced, high-quality products in the most efficient

manner. And that’s exactly what we like best at Syntace!"

-

The Old Mill, inconspicuously located in a small valley, is where Syntace has been manufacturing its products for the last 25 years. The focus being on stems, handlebars, pedals, seatposts and wheels. Jo Klieber also deals in frames and complete bikes. The most recognized bike being the Liteville 301. Liteville, located not too far away, in Wiggensbach in the Allgäu, deals with frame construction and Syntace focuses on developing the components mentioned above.

-

Back to Tacherting, at the two locations there are 35 employees working together. Even though the Old Mill has a unique charm, one that no employee wants to miss, the challenge is bridging the gap between the Old Mill, wheel manufacturing and the warehouse. For this purpose E-bikes, an Electric car and walking are all used. To contact Wiggensbach or the Asian manufactures video conferences are set up.

-

It doesn’t matter where something is built; instead it depends on how it is built and what materials it is manufactured with.

The Mill’s charm

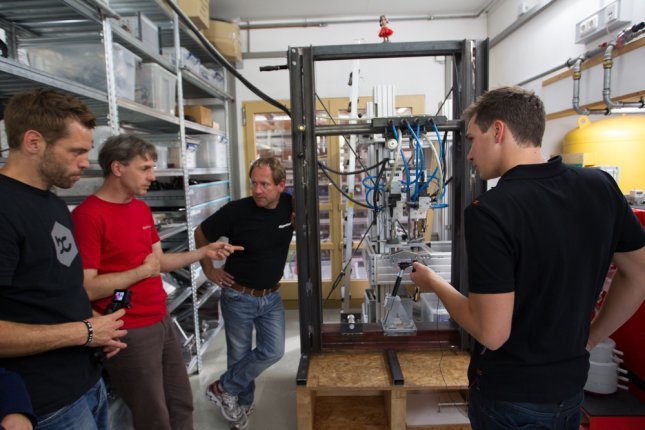

When we walked into the Mill, we felt its charm immediately. On the ground floor are the test machines for quality testing, prototypes, and long-term testing.

-

Next to this is where the frames are welded, sandblasted, and painted. We saw a 3D printer and a diverse array of sanders each with a different duty.

-

Syntace is a small engineering business that can take every idea and turn it into a prototype. The machines, raw materials and the know-how are always available and ready for use.

-

Using a set of small stairs, we headed up to the first floor. Walking past shelves full of handlebars, stems, and pedals waiting to ship we landed in the office. A friendly greeting from Tom awaited us. bike-components and Syntace have had a close relationship for years and at this point it means more than just business.

-

Over coffee our first impressions were allowed to sink in. The mixture of the charm of the Old Mill paired with the know-how and the small machine workshop on the ground floor make this company even more likable.

-

In the conference room we noticed the Readers‘ Awards from every possible magazine. They are especially proud of the Freeride’s 3rd place finish from Eurobike 2015. With this award, Liteville won the third place for the best complete bike brand. Congratulations!

Long-term test on the balcony

The tour starts on a sun-filled terrace that is also used for testing. On the terrace, the UV resistance over time of different products is checked.

-

Here, Syntace’s practical approach to testing shines through. The parts are left in the sun, rain, and snow for years just to see how the surface is affected.

-

As the tour continues, we walk up steep and narrow stairs, past the resident cat in charge of rodent control, before we are abruptly standing in front of a refrigerator where labels and toner are stored.

-

Good performance requires organized storage.

-

On the next level, we find ourselves standing in front of the box of rarities and Tom pulls out a VRO stem.

-

Next to that are Syntace Jo-Jos, or Jo Klieber Yo-Yos, that are not only for fun, but can be used as a plumb line to help make proper adjustments. When looking at all the spare parts here there is a feeling that they are being kept forever to make sure the customer can always be helped. If at some point you get stuck and need an answer to a problem, you can always call Syntace and you will be helped. And that’s a promise.

-

Once out of the Mill we head across the street to wheel production. Syntace hubs are produced in Allgäu and are laced and finished here in Tacherting.

-

Next to wheel production, are the wheel test stands and the archive.

-

In the archive, all products are kept for 12 years for quality assurance.

-

On top of the 2 year warranty required by law, Syntace offers a 10 year guarantee that begins when you buy one of their products and protects against material and manufacturing defects.

On Liteville frames, Syntace offers a 10 year (5+5) guarantee on all material and manufacturing defects. For the first 5 years frame repair and crash replacement are included free of charge. For the following five years, the customer enjoys the same warranty service paying a flat fee.

-

After our visit to Syntace we clearly understood why components can be so expensive. Syntace puts emphasis on the quality and development of their products. With that, Syntace has proven its place in the bicycle market. Moreover, here is Tom’s answer to why Syntace manufactures in Taiwan:

The know-how in Taiwan, in relation to bicycle production, is at the peak level that is sought after in Germany.